Surface preparation for adhesive tape applications

Most substrates are best prepared by cleaning with a 50:50 mixture of isopropyl alcohol (IPA) and water* prior to applying Adhesive Tapes. However, there are exceptions!

Exceptions to this general procedure that may require additional surface preparation include:

- Heavy Oils: A degreaser or solvent-based cleaner may be required to remove heavy oil or grease from a surface and should be followed by cleaning with IPA/water.

- Abrasion: Abrading a surface, followed by cleaning with IPA/water, can remove heavy dirt or oxidation and can increase surface area to improve adhesion.

- Adhesion Promoters: Priming a surface can significantly improve initial and ultimate adhesion to many materials such as plastics and paints.

- Porous Surfaces: Most porous and fibered materials such as wood, particleboard, concrete etc. need to be sealed to provide a unified surface.

- Unique Materials: Special surface preparation may be needed for glass and glass-like materials, copper and copper containing metals and plastics or rubber that contain components that migrate (e.g. plasticizers).

General Procedure

To obtain optimum adhesion with adhesive tapes, the bonding surfaces must be well unified, clean and dry. Typical surface cleaning solvents are IPA/water mixture (rubbing alcohol) or heptane. Bond strength is dependent upon the amount of adhesive-to-surface contact developed. Firm application pressure develops better adhesive contact and helps improve bond strength. Generally, this means that the tape should experience at least 15 psi (100 kPa) in roll down or platen pressure.

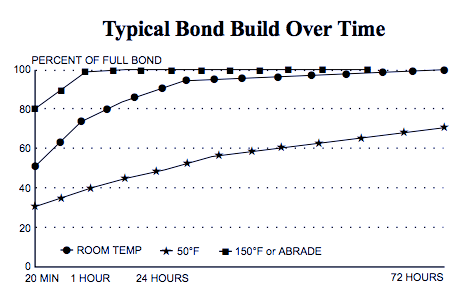

After application, the bond strength will increase as the adhesive flows onto the surface. At room temperature, approximately 50% of the ultimate strength will be achieved after 20 minutes, 90% after 24 hours and 100% after 72 hours.

Source: 3M