Bonding Plastics? Let’s choose the right solution!

Last week some of our team members updated their knowledge on bonding plastics during the webinar from 3M about Adhesives and tapes for bonding plastics. In their latest webinar; 3M experts introduced the different categories of plastics that exist and the importance of surface energy. As we like to share knowledge we summarized our findings after the webinar for you.

Plastics and composite materials become more common for manufacturers to use as alternatives to traditional metals in design and assembly applications. Their advantages are numerous such as durability, aesthetic value, light-weight, etc. But is there an effective way of bonding plastics or composite materials? Off course, let’s explain it to you!

The traditional mechanical fasteners (e.g. rivets, bolts…) work well for metal-on-metal bonding, but they risk damaging ductile plastics and composite materials (cracks). Various plastics welding techniques are also available, but limited in their use and high cost. As an alternative solution, pressure-sensitive adhesives and glues are highly coming to the forefront because they address many of the bonding issues. However, tapes and adhesives result in another set of challenges and this blog learns you how to overcome them.

The ASPEC-method below is a good starting point of selecting the right solution for your plastic bonding application:

- Assembly: “What is being assembled? What are the overall performance needs of the assembly?”

- Substrate: “What are the materials that need to be bonded? What is the surface like?”

- Process: “What is the current process? Does a new solution need to fit into the current process, or can this be improved for the new process?”

- End use: “How and where is the final product used? What are the environmental factors?”

- Cost: “What is the overall cost of the application process? Are there any quality or productivity issues?”

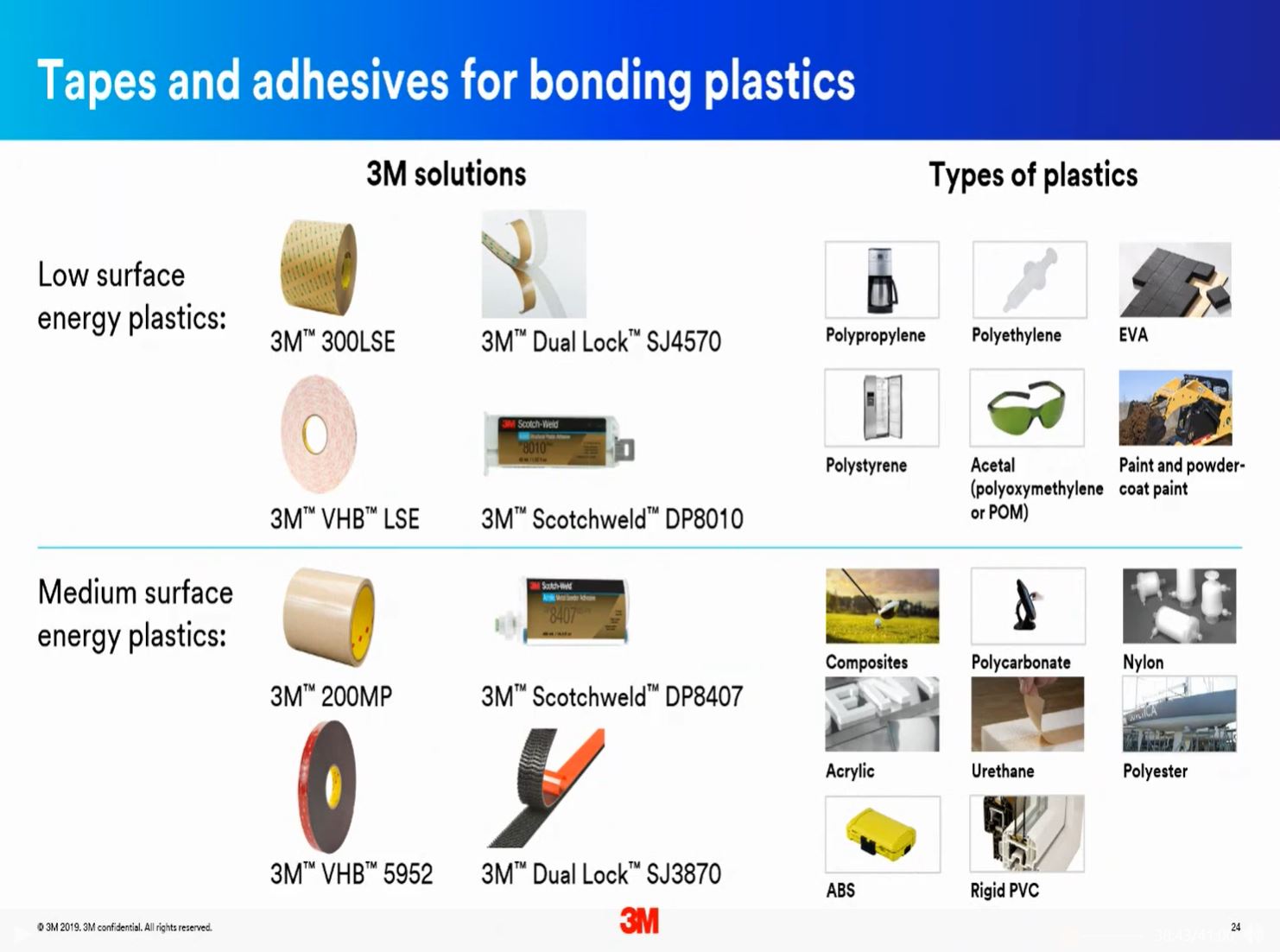

Some plastics and composites don’t present any problems when bonding with adhesives and provide excellent strength, for example rigid PVC, polycarbonate, ABS, polyester, carbon fiber-reinforced epoxy composites, etc. These materials have a medium surface

energy and are quite easy to bond. For more information about ‘surface energy’, we would like to refer to our blog article about ‘Low Energy Surface or High Energy Surface?’.

Properly bonding of LSE plastics (e.g. PE, PP, PTFE, EVA, PVF, acetal, PS, etc.) has traditionally required substantial time and effort to be spent on surface treatment. No contamination (dust, oil, fingerprints…) is allowed on the substrate and additional surface treatment steps are highly recommended. Priming, plasma or corona treatment energize the substrate surface to change the surface properties for better adhesion. Fortunately, specialty adhesives and tapes also exist that can bond these LSE materials without the need for ‘expensive’ surface-preparation steps. An example of a specialty tape is 3M 300LSE tapes with a lot of different types and dimensions. These pressure-sensitive tapes are a proven solution for plastics assembly in a broad spectrum of markets, including electronics, automotive, industrial and medical applications.

Let’s summarize briefly: ‘plastics bonding applications require the use of specialty tapes and adhesives.

Would you like to know how Tacon can help to integrate 3M solutions for bonding plastics in your application, please send us the answers on the ASPEC method of your application through below form!’