Selecting the right Converting Partner for Medical Device

The main question in the landscape of medical adhesives is; how do you choose the best medical adhesive to attach one substrate to another? How can you improve the efficiency and accuracy of diagnostic devices? These questions should always be answered already while your wearable device is still on the drawing board.

Our extensive network of adhesive manufacturers offer a wide range of medical-grade tapes, adhesives and film components already used by medical device manufacturers all over the world. This includes more aggressive tapes, skin-adhesives and closures used in the structure of medical devices made from plastic films, foams and fabrics.

While involving our engineers already at the product conception stage, you can take advantage of this expertise to potentially speed up your design process and creating a prototype or a minimum viable product (MVP) with the best solutions in the market that help improve your device reliability, enhance performance and reduce costs. At the same time, you gain access to our partner’s technology portfolio, which allow you to expand your design options as well as resources that include manufacturing guidance, research and development, and product testing. Whatever product development stage you’re at, we’re ready to help you succeed, by delivering creativity, sharing knowledge and offering our network of adhesive suppliers including Flexcon, Nitto, Avery Dennison, 3M and many more.

Manufacturing technologies and services

When partnering with Tacon/Matrix you have direct and ongoing access to a multidisciplinary team of R&D experts to help your bringing your concept to life!

We offer an integrated platform of technologies, services and network that makes your manufacturing process efficient, reduce costs and decrease time-to-market.

Included services you can expect are:

- Research & Development

- Regulatory Guidance

- Quality Assurance through ISO 13485 (through Matrixtape)

- Clean manufacturing and assembly

- Packaging and logistics

Together with our expertise in converting adhesive materials and our extensive network of manufacturing partnerships simplify the supply chain by vertically integrating materials and finished product. This provide us a chance to follow you vision, schedule and budget at every stage and bring your product quickly to the market. Our large network of manufacturers offer competitive pricing on raw materials.

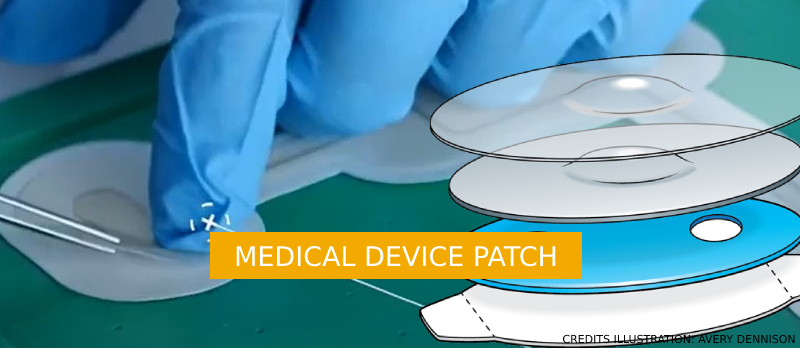

Innovation at every layer of your device

From how the selected materials work together with the skin to how they help the medical industry, we will make sure that every layer is designed to support comfort, wearability, conformability and overall performance.

Converting/ Assembly layer adhesives

The carefully selected materials must connect the components of the wearable device. Even though they do not directly touch the skin of the patient, the materials must be compliant with the skin contact layer. Each selected layer need to be laminated in a dust free production area like a cleanroom available at Tacon/Matrix.

Skin contact adhesives

Skin contact adhesive materials connect the wearable device directly to the skin of the patient. They must connect securely and comfortable to the skin while allowing the skin to breath and must accommodate moisture levels.

Through our extensive network of partners and suppliers we can offer you single coated products that have wear times of 24 hours till 21 days. These wearable tapes have silicone, rubber and acrylic adhesive coatings. Some of these products are coated on Non-Woven carriers (PE, PET and PU). The variables with these non-woven PE, PET and PU is the stretch and breathability of the Non-woven material. Another variable about the non-woven carrier is the ability for the carrier to be sonic welded. PET non-woven carriers are the common material that is used when device manufacturers are sonic-welded the skin contact patch to the actual device. Also the availability exist to have short term wearable single coated silicone tapes as well as foam tape carriers (PE, EVA, PolyOlefin). Wearable foam tapes are a great option for quick stick monitoring devices that are only intended to be on the skin for 3 days or less.

Are you working on a wearable device and need support to convert your idea to a real product?

Feel free to share your idea with us and let’s see how we can support you!